China C-Type Servo Press Machine manufacture: Revolutionizing Industrial Automation

In recent years, the field of industrial automation has witnessed significant advancements, offering new possibilities for increased productivity and efficiency. Among these innovations, the introduction of C-Type servo press machines has revolutionized the manufacturing industry. These machines, with their precise control and superior performance, have become an essential tool for companies looking to stay competitive in today’s fast-paced market.

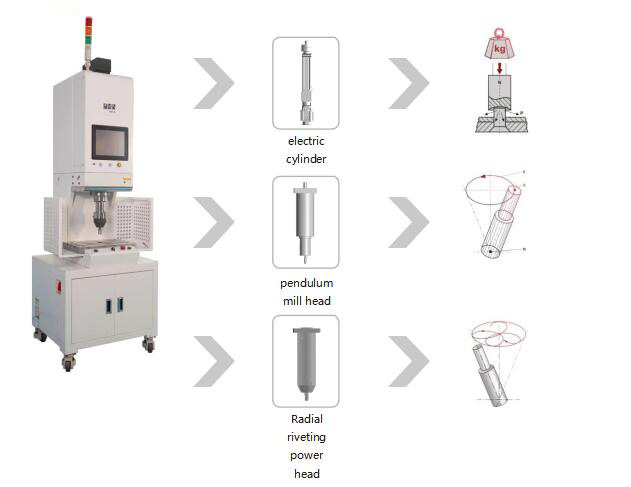

C-Type servo press machines are characterized by their unique design, which includes a C-shaped frame. This structure ensures stability and maximizes the use of space, allowing for smooth and accurate operations. The servo motor, combined with an advanced control system, provides high precision and control over the pressing force, speed, and position. This level of accuracy translates into consistent and reliable results, reducing the risk of errors and ensuring product quality.

One of the key advantages of C-Type servo press machines is their versatility. These machines can handle a wide range of tasks, from simple punching and bending to complex forming and embossing operations. With programmable settings, operators can easily adjust the machine’s parameters to accommodate different materials, shapes, and sizes. This flexibility makes C-Type servo press machines suitable for various industries, including automotive, aerospace, electronics, and appliance manufacturing.

The introduction of servo technology in press machines has also contributed to significant improvements in energy efficiency. Traditional hydraulic or pneumatic systems often consume excessive energy due to their continuous operation. In contrast, servo-driven systems only consume energy when required, resulting in substantial energy savings. This not only benefits the environment but also reduces production costs for businesses.

Another remarkable feature of C-Type servo press machines is their user-friendly interface. The control panel allows operators to monitor and adjust various parameters with ease, ensuring smooth operation and minimizing the learning curve. Additionally, many machines come equipped with advanced safety features, such as sensors and emergency stop buttons, providing a secure working environment.

Furthermore, C-Type servo press machines offer increased productivity and shorter production cycles. The precise control over the pressing force and speed allows for faster operation, minimizing downtime between tasks. Moreover, the ability to program and store different settings enables quick changeovers, reducing setup time and increasing overall efficiency. Manufacturers can expect higher output and improved production rates, leading to a more competitive position in the market.

While C-Type servo press machines offer numerous benefits, it is essential to consider certain factors when choosing the right machine for specific applications. Factors such as required pressing force, stroke length, and available space should be carefully evaluated to ensure optimal performance. Consulting with experts and conducting thorough research can help businesses make informed decisions and select the most suitable machine for their needs.

In conclusion, C-Type servo press machines have revolutionized industrial automation by offering precise control, versatility, energy efficiency, and user-friendly interfaces. These machines have become indispensable tools for manufacturers seeking to enhance productivity, reduce costs, and improve product quality. As technology continues to advance, we can expect further developments in servo press machines, opening up new possibilities for the manufacturing industry.

- Desktop four-column servo press: an efficient and precise industrial tool

- In modern industrial manufacturing, with the continuous improvement of product quality and production efficiency requirements,...

- Precise control of servo printing machines, the secret to improving printing quality and production efficiency

- Servo printers can significantly improve printing quality and production efficiency through precise control. Here are...

- Servo printer: intelligent equipment leading the new era of efficient printing

- With the rapid development of science and technology, the printing industry has also ushered in...

- Multifunctional Servo Riveting Machine: How to achieve efficient and accurate riveting process?

- In modern manufacturing, multifunctional servo riveting machine has become an indispensable equipment in many industrial...

- Motorcycle Engine Bracket Servo Press: The Power of Precision Manufacturing

- In the motorcycle manufacturing and assembly process, the engine mount is a key component that...

- Electric Lubricator: a powerful assistant in the field of lubrication

- Electric grease machine, a powerful assistant in the field of modern industrial lubrication, plays an...