Desktop-Mini-Viersäulen-Pressmaschine PJL-S-5KN

1.The main function

The Pinjialing servo press is driven by an AC servo motor. It changes the rotational force into the vertical direction through a high-precision ball screw. It relies on the pressure sensor loaded on the front end of the driving part to control and manage the pressure. It relies on the encoder to control the speed and position. At the same time, it controls the speed and position. A device that applies pressure to the work object to achieve the purpose of processing. It can control the pressure/stop position/driving speed/stop time at any time. It can realize the whole-process closed-loop control of the pressing force and the pressing depth in the pressure assembly operation; it adopts user-friendly human-machine The touch screen of the interface is intuitive and easy to operate. Through high-speed collection of pressure-position data during the press-fitting process, online quality judgment and data information management of precision press-fitting are realized.

Equipment mechanical structure

The fuselage is made of ductile iron frame-type one-piece casting, which has higher strength and stability. The guardrails are made of transparent PC boards, and the carbon steel parts are hard chromium plated, oiled and other anti-rust treatments.

|

|

2. Equipment specifications and main technical parameters

| Device name | Intelligent servo press machine |

| Device model | PJL-S-5KN |

| positioning accuracy | ±0.01mm |

| Pressure detection accuracy | 0.5%F.S |

| greatest pressure | 5kN |

| pressure range | 50N-5kN |

| Displacement resolution | 0.001mm |

| Data collection frequency | 1000 times per second |

| Maximum stroke | 150mm |

| closed height | 350mm |

| Throat depth | 175mm |

| Indenter mold size | Inner diameter Φ20mm, depth 25mm |

| Pressing speed | 0.01-35mm/s |

| fast forward speed | 0.01-125mm/s |

| Minimum speed can be set | 0.01mm/s |

| compress time | 0-99s |

| equipment power | 750W |

| Device memory | 500GB |

| Supply voltage | 1~AC220V 50HZ |

| Weight approx. | 110kg |

3. Main components and brands of equipment

| Component name | quantity | brand | Remark |

| driver | 1 set | INOVANCE | |

| servo motor | 1set | INOVANCE | |

| Servo cylinder | 1set | Pinjialing | Independent research and development |

| Safety grating | 1set | Well-known domestic brands | |

| Touch screen all-in-one machine | 1set | Hotntech | 10 inch color |

| Control card + system | 1 set | Pinjialing | Independent research and development |

| Pressure Sensor | 1 | Well-known domestic brands | |

| transformer | 1 | Well-known domestic brands | |

| relay | 1 | Schneider | |

| air switch | 2 | Schneider |

4. Dimensional drawing

|

|

5. Main configuration of the system

| serial number | Main components |

| 1 | Single chip control board |

| 2 | Touch screen all-in-one machine |

| 3 | Pressure Sensor |

| 4 | server system |

| 5 | Servo cylinder |

| 6 | Safety grating |

| 7 | switching power supply |

6. System software main interface

The main interface includes interface jump buttons, data display and manual operation functions.

Management: Contains jump interface program backup, shutdown, and login method selection.

Settings: Contains jump interface units and system settings.

Reset to zero: clear the load indication data.

View: Language settings and graphical interface selection.

Help: version information, maintenance cycle settings.

Test plan: Edit the pressing method.

Redo a batch: Clear the current pressing data.

Force: Real-time force monitoring.

Displacement: real-time press stop position.

Maximum force: The maximum force generated during the current pressing process.

Manual control: automatic continuous descent and rise, inching rise and fall; test initial pressure.

7. Equipment characteristics

1. High equipment accuracy: displacement accuracy ±0.01mm, pressure accuracy 0.5%FS.

2. The software is independently developed and easy to maintain.

3. Various pressing modes: optional pressure control, position control.

4. The equipment is equipped with a safety grating to ensure the safety of operators.

5. Achieve precise displacement and pressure control without the need for hard limits and reliance on precision tooling.

6. Online assembly quality management technology detects defective products in real time.

7. Specify the optimal press-fitting process according to specific product requirements.

8. Specific, complete and accurate operation process recording and analysis functions.

9. Self-diagnosis function: When the equipment fails, the servo press can display an error message and prompt a solution, making it easy to quickly find and solve the problem.

10. The software sets multiple permission setting functions, such as administrator, operator and other permissions.

Advantages:

1. The fuselage is made of ductile iron frame-type integrated casting, which has higher strength and stability.

2. The guardrail is made of transparent PC board, which has high anti-collision strength and good light transmission. The entire body gives people a transparent and intuitive visual aesthetic feeling.

3. The overall equipment is lightweight and portable, and is suitable for pressing and mounting small precision products such as electronic products, clocks, and medical equipment on production line work surfaces and laboratory environments.

8. Application fields

• Precision press-fitting of automobile engines, transmission shafts, steering gears and other parts

• Precision press mounting of electronic products

• Precision pressing of core components of imaging technology

• Motor bearing precision press fitting application

• Precision pressure testing such as spring performance testing

• Automated assembly line applications

• Press assembly application of aerospace core components

• Medical and power tool assembly

• Other occasions requiring precision pressure assembly

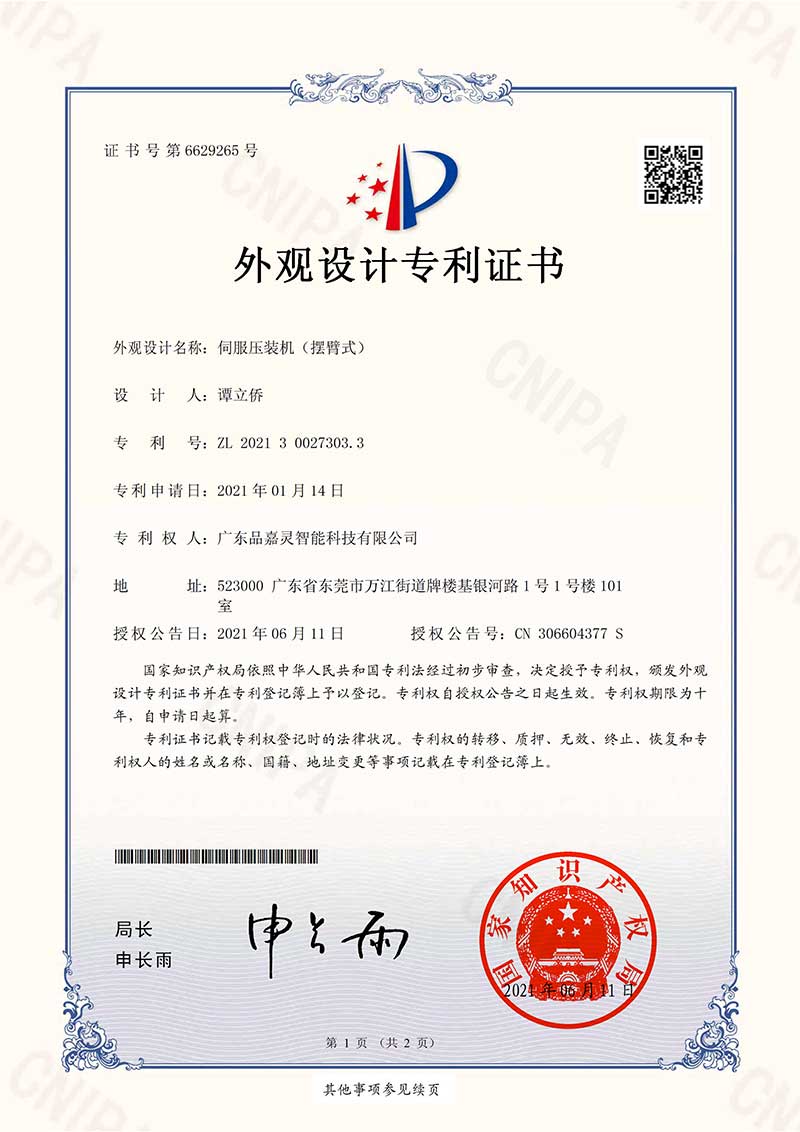

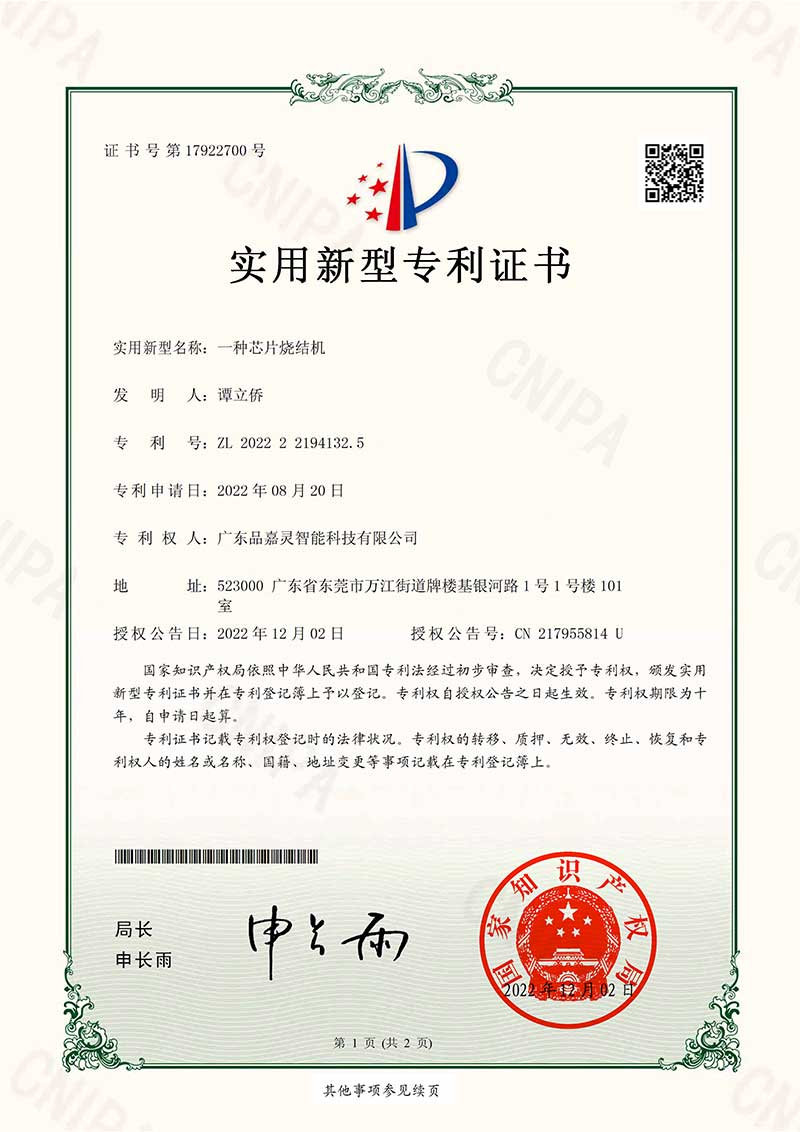

We have obtained various international management system certifications and comply with production standards in different regions.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Why should I buy from your company not from other suppliers?

- What is the maintenance required for a servo press machine?

- Is there any warranty after purchasing the servo press?

- What is the accuracy of the servo press?

- What is a servo press machine?