Fournisseurs de machine de rivetage radiale de riveteuse servo Chine

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is Motorcycle engine cradle servo press?

Manual auxiliary loading and unloading of the cradle, automatic loading of the bushing, automatic installation of the pivot tube rubber sleeve, and automatic pressure installation of the bushing.

The equipment mainly consists of: casting frame, automatic loading and unloading system, multi-station turntable, servo pressing system, human-computer interaction system, safety protection system and other parts.

- Is it easy to use?

Yes, it’s easy to use. Just pour cream into the machine, turn it on and let it do the churning for you.

- Is there any warranty after purchasing the servo press?

We have more than 13 years of professional manufacturing experience. We provide 2 years warranty for our servo presses. Technical support is provided free of charge forever.

- How many types of riveting machines do we have in our factory?

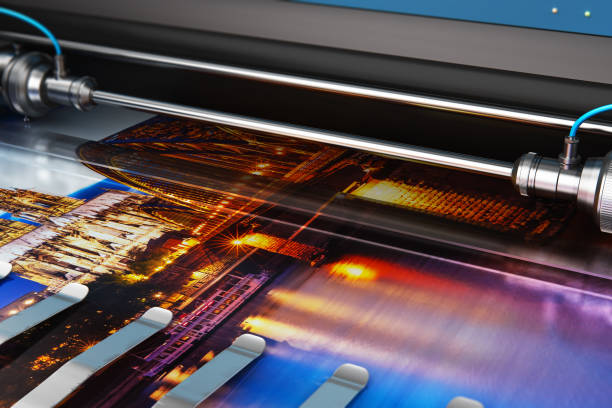

Our factory has S / C type precision intelligent servo press equipment, high precision diameter riveting, pendulum riveting, servo rotary riveting machine.

- What is the use of Servo Riveting Machine?

Guangdong Pinjialing Intelligent Technology Co. Ltd. is a professional servo press, precision coating and related equipment R & D and manufacturing as one of the modern technology-based enterprises. Our servo riveting machine is used to automatically set (press) rivets to join materials together. The riveting machine offers greater consistency, productivity and lower cost compared to manual riveting.

- How does an electric churn work?

The Electric Butter Machine has a motorized churn that rotates and agitates the cream, causing the fat globules to coalesce and separate from the buttermilk, resulting in fresh butter.

- How to place order?

When you are ready to order, please contact us for confirm the suitable solution & plan & model. What cannot be ignored is you should provide a copy purchase order to ensure that your order is processed properly.

- What is the maintenance required for a servo press machine?

A servo press machine requires regular maintenance, including lubrication, checking for wear of components, and calibration of the servo motor. Regular maintenance ensures optimal performance and longevity of the machine.

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.