Prodotto da tavolo per presse a quattro montanti in Cina

| modello | PJL-S-0.5T/1T/2T | Weight(KG) | 80 |

| Maximum pressure (T) | 0.5/1/2 | Maximum speed(mm/s) | 150 |

| Effective stroke(mm) | 100-150( customizable) | Pressing speed (mm/s) | 0.01-35 |

| Closed mold height (mm) | 350 | Holding time (s) | 0.1-200 |

| Profondità della gola (mm) | 200 | Positioning accuracy (mm) | ±0.01 |

| Force resolution (%) | 0.005 | Pressure Accuracy (%F.S) | 0.5 |

| Displacement resolution (mm) | 0.001 | Dimensions (mm) | 675*401*950 |

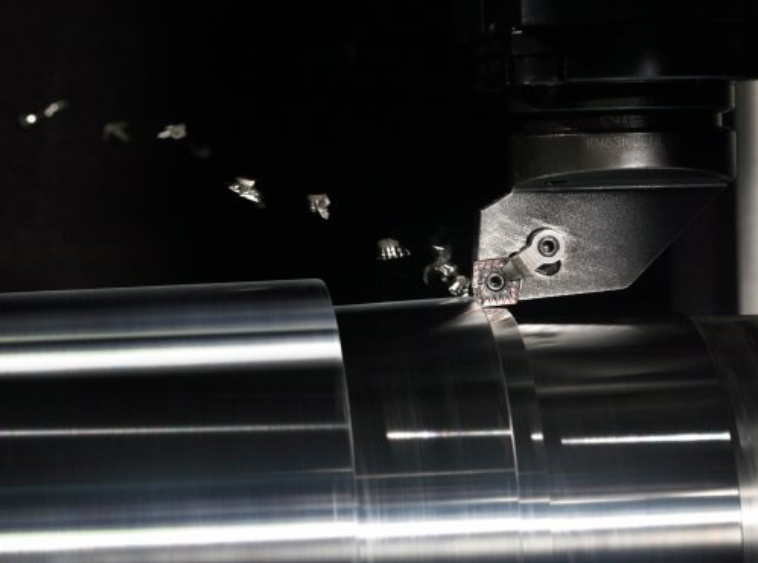

The four-station tabletop press is a high-efficiency device driven by an AC servo motor. It cleverly uses high-precision ball screws to convert rotational force into vertical force, ensuring precise and stable power transmission. The pressure sensor installed at the front end of the equipment is responsible for real-time pressure sensing and monitoring, and precise control and management of pressure can be achieved through accurate data feedback. This precise control method not only improves processing efficiency, but also ensures stable and reliable processing quality.

Pinjialing always adheres to the principle of “customer first” and is committed to becoming your most reliable partner. We focus on developing and providing high quality servo punching equipment, coupled with excellent technical support, and strive to create efficient, stable and low maintenance cost solutions for operators. We know that only by truly standing from the customer’s perspective and understanding their needs and pain points can we create greater value for them.

Pinjialing not only provides advanced equipment, but is also committed to helping customers improve production efficiency, reduce operating costs and achieve sustainable development through our efforts. We know that every small improvement can bring significant benefits to our customers. Therefore, we always insist on being driven by innovation and constantly optimize products and services to meet the growing needs of customers.

If you are interested in our innovative products and high-quality services, or if you have any questions or needs, please feel free to contact us. We will wholeheartedly provide you with more information, explore the possibility of cooperation with you, and create a better future together.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Is it safe to use?

Yes, the Electric Butter Machine is safe when used according to the manufacturer’s instructions. Always follow the safety guidelines and precautions outlined in the instruction manual.

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.

- Is it easy to use?

Yes, it’s easy to use. Just pour cream into the machine, turn it on and let it do the churning for you.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.

- How does an electric churn work?

The Electric Butter Machine has a motorized churn that rotates and agitates the cream, causing the fat globules to coalesce and separate from the buttermilk, resulting in fresh butter.

- What safety precautions should I follow when operating a servo press machine?

When operating a servo press machine, it is important to follow all safety protocols, including wearing appropriate personal protective equipment, using safety guards and devices, and obtaining proper training on the machine’s operation. Additionally, only trained and authorized personnel should operate the machine.

- How do I select the right servo press machine for my application?

When selecting a servo press machine, it is important to consider factors such as the required forming force and stroke, the material to be formed, and the required production volume. Consult with a reputable supplier to ensure that the machine meets your needs and requirements.

- What is a servo press machine?

A servo press machine is a type of press machine that uses a servo motor to drive the ram. It provides precise control over the stroke and speed of the ram, allowing for accurate and repeatable forming processes.

- How is a servo press machine different from a mechanical press machine?

A servo press machine differs from a mechanical press machine in that it employs a servo motor that provides precise control over the ram’s position and speed, while a mechanical press machine uses a flywheel and clutch to control the ram.

- Which payment terms you can accept?

We can accept flexible payment methods including Bank Transfer, LC, DP, Western Union, Paypal or combined terms as negotiated.