Servo Electric Cylinder manufacture: Revolutionizing Precision Motion Control

Introduction

Precision motion control plays a significant role in various industries, such as manufacturing, robotics, and automation. Traditional hydraulic and pneumatic systems have long been used for this purpose, but they come with drawbacks like high maintenance costs, leakage issues, and limited control options. In recent years, cilindri servoelettrici have emerged as a revolutionary solution, offering enhanced precision, efficiency, and flexibility.

What is a Servo Electric Cylinder?

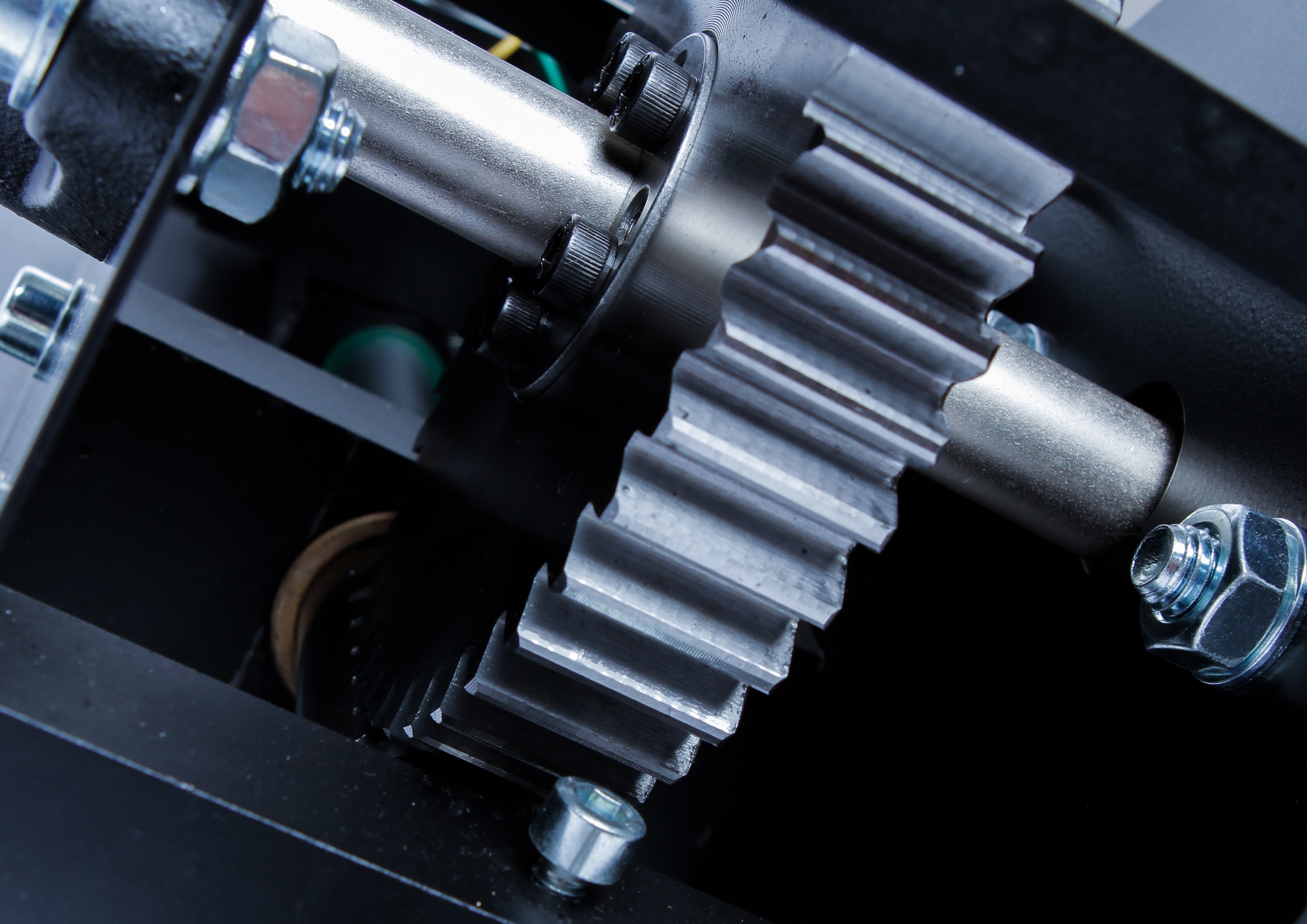

A servo electric cylinder is an electromechanical actuator that converts rotary motion into linear motion. It consists of a motor, a ball screw or a belt drive, and a feedback device such as an encoder. This combination enables precise and controlled linear movement with high accuracy, repeatability, and speed.

Advantages over Hydraulic and Pneumatic Systems

Servo electric cylinders offer several advantages over traditional hydraulic and pneumatic systems:

1. Precision: Servo electric cylinders can achieve high positioning accuracy, typically within micrometers. This level of precision is crucial in applications that require delicate movements or exact positioning.

2. Efficiency: Hydraulic and pneumatic systems often suffer from energy losses due to friction, leaks, and heat generation. Servo electric cylinders are more energy-efficient as they only consume power when in motion, resulting in substantial energy savings in the long run.

3. Flexibility: Servo electric cylinders provide greater flexibility in terms of control options. They can be easily integrated with programmable logic controllers (PLCs) and computer numerical control (CNC) systems, allowing for complex motion profiles and easy adjustments to match specific application requirements.

4. Maintenance: Unlike hydraulic systems that require regular maintenance, such as oil changes and filter replacements, servo electric cylinders have fewer maintenance needs. They are also cleaner, as they do not produce hydraulic fluid leaks or emissions.

Applications

Servo electric cylinders find applications in various industries, including:

1. Manufacturing: These cylinders are used in precision assembly, pick-and-place operations, and material handling systems, where accurate and repeatable movements are crucial for efficient production processes.

2. Robotics: Servo electric cylinders play a vital role in robotics, ensuring precise control of robot arms and grippers. They enable robots to perform tasks with high accuracy and speed, such as welding, painting, and packaging.

3. Packaging: In the packaging industry, servo electric cylinders are used to control the precise movement of conveyor belts, filling machines, and labeling systems. This ensures accurate packaging, reduces material waste, and improves productivity.

4. Medical: Precision is paramount in medical applications, such as surgical robots, prosthetics, and diagnostic equipment. Servo electric cylinders enable precise movements in these devices, enhancing patient safety and treatment outcomes.

Conclusion

Servo electric cylinders have revolutionized precision motion control, offering enhanced accuracy, efficiency, flexibility, and ease of maintenance compared to traditional hydraulic and pneumatic systems. With their wide range of applications in manufacturing, robotics, packaging, and medical industries, these cylinders are becoming increasingly popular for achieving precise and controlled linear movements. As industries continue to demand higher levels of precision, cilindri servoelettrici are expected to witness further advancements and adoption in the future.

- Electric Lubricator: a powerful assistant in the field of lubrication

- Electric grease machine, a powerful assistant in the field of modern industrial lubrication, plays an...

- How does a fully automatic gear press work and what are its common problems?

- The fully automatic gear press is a kind of mechanical equipment widely used in the...

- What are the precautions for the maintenance of servo riveting machines?

- As a commonly used equipment in modern industry, the maintenance of servo riveting machine is...

- Nanosilver Sintering Machine: Technology and Application Analysis

- As a key packaging equipment, nanosilver sintering machine plays an important role in modern semiconductor...

- Precision metering valve: a precise tool in industrial control

- As a key component in the field of industrial fluid control, precision metering valve plays...

- Desktop Mini Four-Column Press: Efficient, Stable and Safe Micromachining Tool

- In the wave of precision manufacturing and miniaturization production, the desktop mini four-column press stands...