500t servo press machine factory

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is the use of Servo Riveting Machine?

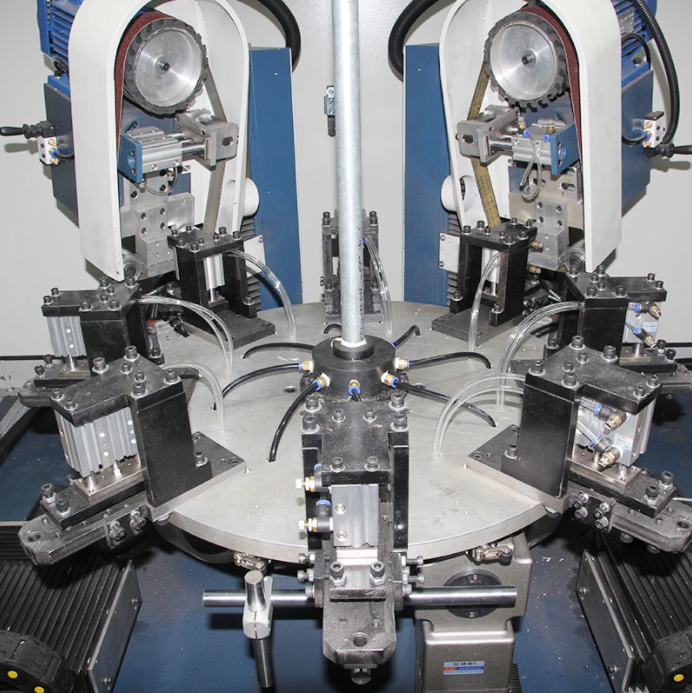

Guangdong Pinjialing Intelligent Technology Co. Ltd. is a professional servo press, precision coating and related equipment R & D and manufacturing as one of the modern technology-based enterprises. Our servo riveting machine is used to automatically set (press) rivets to join materials together. The riveting machine offers greater consistency, productivity and lower cost compared to manual riveting.

- Is there any warranty after purchasing the servo press?

We have more than 13 years of professional manufacturing experience. We provide 2 years warranty for our servo presses. Technical support is provided free of charge forever.

- Do you have an inspection procedure for the product?

Yes, We have a strict inspection of product quality and packing.

- How does an electric churn work?

The Electric Butter Machine has a motorized churn that rotates and agitates the cream, causing the fat globules to coalesce and separate from the buttermilk, resulting in fresh butter.

- How do I select the right servo press machine for my application?

When selecting a servo press machine, it is important to consider factors such as the required forming force and stroke, the material to be formed, and the required production volume. Consult with a reputable supplier to ensure that the machine meets your needs and requirements.

- What are the advantages of using a servo press machine?

The advantages of using a servo press machine include reduced production costs, increased productivity, improved product quality, and better energy efficiency.

- Which payment terms you can accept?

We can accept flexible payment methods including Bank Transfer, LC, DP, Western Union, Paypal or combined terms as negotiated.

- Which shipping way can you provide?

We can provide shipping by sea, by air, by express and etc according to customer requirements.

- What is a servo linear actuator mechanism?

The servo motor is directly connected with the transmission screw of the electric cylinder, so that the encoder of the servo motor directly feeds back the displacement of the moving piston of the electric cylinder, which reduces the inertia and clearance of the intermediate link, and improves the control and control accuracy.

- What is a Nano silver sintering machine?

Our nanosilver sintering machine is an efficient and environment-friendly nanomaterial preparation equipment product, which focuses on the sintering preparation of high quality nanosilver powder. The product adopts advanced microwave heating technology to effectively control the temperature field distribution and ensure uniform and stable sintering process. Equipped with a sophisticated vacuum system and exhaust gas treatment device to ensure that the sintering process is carried out in a dust-free, low-oxygen environment, thereby improving the purity and dispersion of nanosilver powder.