advanced servo press

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Which shipping way can you provide?

We can provide shipping by sea, by air, by express and etc according to customer requirements.

- What safety precautions should I follow when operating a servo press machine?

When operating a servo press machine, it is important to follow all safety protocols, including wearing appropriate personal protective equipment, using safety guards and devices, and obtaining proper training on the machine’s operation. Additionally, only trained and authorized personnel should operate the machine.

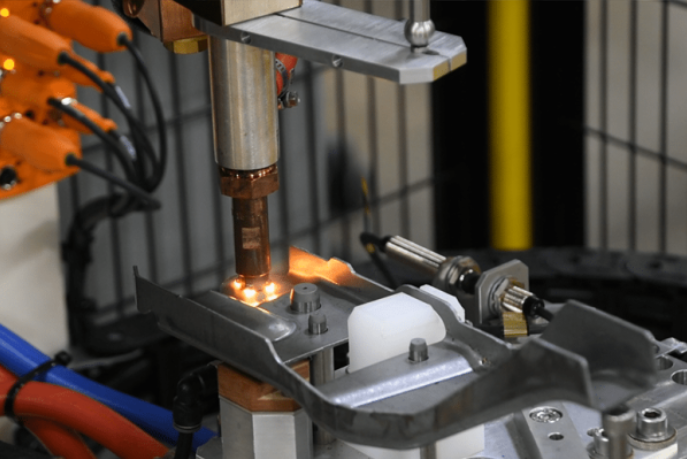

- What is Motorcycle engine cradle servo press?

Manual auxiliary loading and unloading of the cradle, automatic loading of the bushing, automatic installation of the pivot tube rubber sleeve, and automatic pressure installation of the bushing.

The equipment mainly consists of: casting frame, automatic loading and unloading system, multi-station turntable, servo pressing system, human-computer interaction system, safety protection system and other parts.

- What is a Desktop Servo Riveting Machine?

Desktop Servo Riveting Machine are high-torque machines. They are able to produce the output pressing force with full energy at any point of an operation.

- Is it safe to use?

Yes, the Electric Butter Machine is safe when used according to the manufacturer’s instructions. Always follow the safety guidelines and precautions outlined in the instruction manual.

- Is it easy to use?

Yes, it’s easy to use. Just pour cream into the machine, turn it on and let it do the churning for you.

- What is Double Station Turntable Servo Riveting Machine?

The Double Station Rotary Table Servo Riveting Machine consists of a cast body, a double station rotary table, a servo riveting system, a human computer interaction system, and a safety protection system.

- What is a servo press machine?

Guangdong pinjialing Intelligent Technology Co. , Ltd is a professional to servo pressing, Precision coating and Related Equipment R & D and manufacturing as one of the modern technology-based companies. Servo press machines consist of many components, including a servo motor, servo driver, lead screw, PLC, touch screen, timing pulley, timing belt, guide rod, bearings, power switch, and thermal protection.

- How many types of riveting machines do we have in our factory?

Our factory has S / C type precision intelligent servo press equipment, high precision diameter riveting, pendulum riveting, servo rotary riveting machine.

- How does an electric churn work?

The Electric Butter Machine has a motorized churn that rotates and agitates the cream, causing the fat globules to coalesce and separate from the buttermilk, resulting in fresh butter.