中国デスクトップ 4 ポスト プレス機

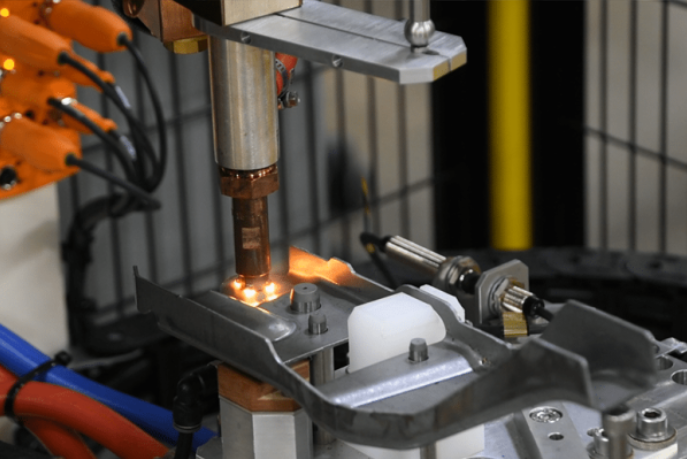

The servo press is an efficient and precise device whose core power comes from an AC servo motor. This motor not only provides excellent stability and reliability, but also ensures constant performance over long periods of operation. The servo press skillfully uses high-precision ball screws to convert the rotational force of the motor into vertical force, providing a powerful driving force for various processing tasks.

Servo presses are also equipped with encoders for precise control of speed and position. By monitoring and adjusting the encoder in real time, the machine can achieve a high degree of accuracy and reliability during processing. The servo press can apply appropriate pressure to the workpiece according to the specific processing requirements, thus achieving the ideal processing effect.

Pressure/stop position/drive speed/stop time can be controlled at any time. It can realize closed-loop control of the entire process of pressing force and pressing depth during press-fitting operations; the touch screen human-machine interface is friendly, intuitive and easy to operate. It is equipped with safety light curtains. During the installation process, if someone reaches into the installation area, the press head will stop in place to ensure safe operation.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is a Desktop Servo Riveting Machine?

Desktop Servo Riveting Machine are high-torque machines. They are able to produce the output pressing force with full energy at any point of an operation.

- How does an electric churn work?

The Electric Butter Machine has a motorized churn that rotates and agitates the cream, causing the fat globules to coalesce and separate from the buttermilk, resulting in fresh butter.

- Do you have an inspection procedure for the product?

Yes, We have a strict inspection of product quality and packing.

- What is the use of Servo Riveting Machine?

Guangdong Pinjialing Intelligent Technology Co. Ltd. is a professional servo press, precision coating and related equipment R & D and manufacturing as one of the modern technology-based enterprises. Our servo riveting machine is used to automatically set (press) rivets to join materials together. The riveting machine offers greater consistency, productivity and lower cost compared to manual riveting.

- What safety precautions should I follow when operating a servo press machine?

When operating a servo press machine, it is important to follow all safety protocols, including wearing appropriate personal protective equipment, using safety guards and devices, and obtaining proper training on the machine’s operation. Additionally, only trained and authorized personnel should operate the machine.

- What is a servo linear actuator mechanism?

The servo motor is directly connected with the transmission screw of the electric cylinder, so that the encoder of the servo motor directly feeds back the displacement of the moving piston of the electric cylinder, which reduces the inertia and clearance of the intermediate link, and improves the control and control accuracy.

- What are the advantages of servo presses in forging?

In addition to making it possible to form materials traditionally considered difficult to machine, our servo presses offer a number of other benefits, including higher forming accuracy, increased productivity, reduced noise, and improved energy savings.

- What is Double Station Turntable Servo Riveting Machine?

The Double Station Rotary Table Servo Riveting Machine consists of a cast body, a double station rotary table, a servo riveting system, a human computer interaction system, and a safety protection system.

- Which shipping way can you provide?

We can provide shipping by sea, by air, by express and etc according to customer requirements.

- Is there any warranty after purchasing the servo press?

We have more than 13 years of professional manufacturing experience. We provide 2 years warranty for our servo presses. Technical support is provided free of charge forever.