What are the types of Servo Press Machines?

Servo press machines have revolutionized the manufacturing industry by offering precise control and flexibility in various applications. These machines utilize advanced servo motor technology to deliver accurate force and speed, ensuring high-quality production. In this article, we will explore the different types of servo press machines and their functionalities.

1. C-Frame Servo Presses:

C-frame servo presses, also known as gap frame presses, are versatile machines used in a wide range of applications. They feature a C-shaped frame that provides accessibility to the working area from three sides. These presses are suitable for tasks such as bending, flanging, pressing, and punching. The servo motor in a C-frame press allows for precise control over the force, speed, and position, making it ideal for intricate operations.

2. H-Frame Servo Presses:

H-frame servo presses, also called straight side presses, are robust machines designed for heavy-duty applications. These presses feature an H-shaped frame that provides stability and reduces deflection during operation, ensuring accuracy and repeatability. H-frame servo presses are commonly used for deep drawing, stamping, and forming operations in industries such as automotive, aerospace, and appliance manufacturing.

3. Four-Column Servo Presses:

Four-column servo presses, also referred to as double-sided presses, are versatile machines that offer balanced force distribution during operation. These presses feature four vertical columns that provide stability and support for heavy loads. Four-column servo presses are often used in applications that require high force and precision, such as metal forming, coining, and assembly tasks.

4. Transfer Servo Presses:

Transfer servo presses are specialized machines used for transferring workpieces between multiple stations during the manufacturing process. These presses feature a conveyor system that moves the parts from one die station to another, allowing for complex operations to be performed. Transfer servo presses are commonly utilized in the production of electrical components, automotive parts, and household appliances.

5. Tandem Servo Presses:

Tandem servo presses consist of two or more presses connected in series, allowing for simultaneous and synchronized operations. These presses are ideal for large-scale production environments where high throughput and efficiency are required. Tandem servo presses are commonly used in the automotive industry for operations such as panel forming, deep drawing, and trimming.

結論は、 servo press machines are available in various types to cater to different manufacturing requirements. Whether it is a C-frame, H-frame, four-column, transfer, or tandem servo press, each machine offers unique features and functionalities to enhance productivity and precision. The implementation of servo press machines has undoubtedly transformed the manufacturing landscape, enabling manufacturers to achieve higher quality and efficiency in their production processes.

- Electric Lubricator: a powerful assistant in the field of lubrication

- Electric grease machine, a powerful assistant in the field of modern industrial lubrication, plays an...

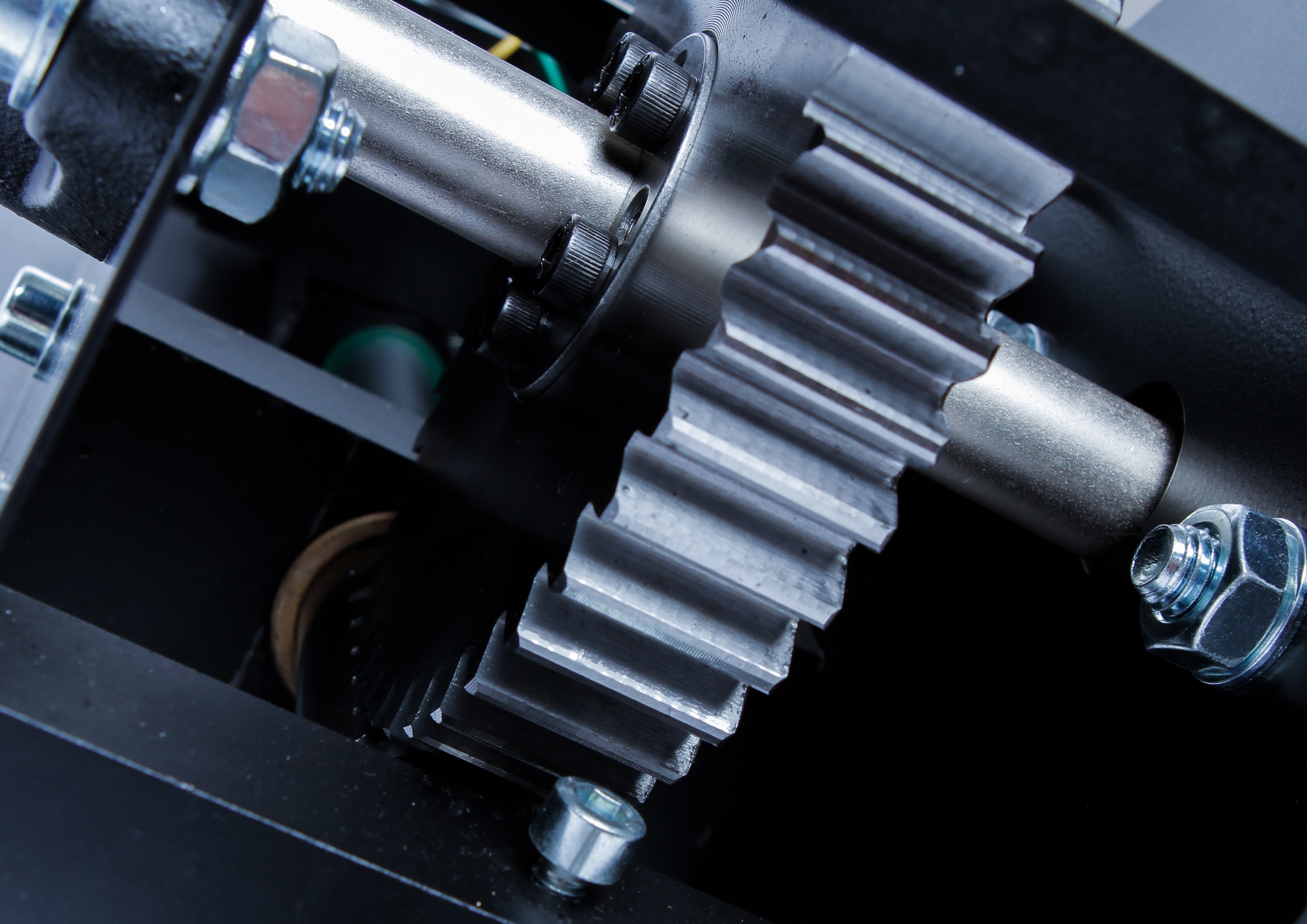

- 全自動ギアプレスはどのように機能し、よくある問題は何ですか?

- 全自動ギアプレスは、業界で広く使用されている機械設備の一種です。

- サーボリベットマシンのメンテナンスの際の注意事項は何ですか?

- サーボリベットマシンは現代の産業で一般的に使用されている機器であるため、メンテナンスは重要です。

- ナノ銀焼結機:技術と応用分析

- ナノ銀焼結機は、主要なパッケージング機器として、現代の半導体製造において重要な役割を果たしています...

- 精密計量バルブ:産業用制御における精密ツール

- 工業用流体制御の分野における重要なコンポーネントとして、精密計量バルブは重要な役割を果たします...

- デスクトップミニ4コラムプレス:効率的で安定性と安全性に優れたマイクロ加工ツール

- 精密加工と小型化生産の波の中で、卓上ミニ4コラムプレスは...