중국 서보프레스 제조사 제품

Pinjialing brand, the capacity of ALC series power press machine can be 250T, 300T, 400T, 500T, 630T. Punching machine Stamping Mold Save Energy 30% . ISO /CE certificate approved.

The core products are S /C type precision intelligent servo pressing equipment, high precision diameter riveting, pendulum riveting, servo rotating riveting machine, high precision chip sintering pressing machine, high-performance electric yellow oil pump/dispensing pump, high precision quantitative grease valve/dispensing valve, precise air control flow valve, and ultra- precision servo quantitative valve.

Technical support and customer service

Our after-sales service team is always customer-focused and provides a full range of service guarantees. From equipment installation and troubleshooting to daily maintenance and upkeep, we will wholeheartedly provide customers with thoughtful services. Our after-sales service personnel will regularly visit customers to understand the use of the equipment, detect and solve problems in a timely manner, and ensure the stable operation of the equipment.

We have also established a complete customer feedback mechanism and actively collect customer opinions and suggestions. Customer feedback is an important basis for us to improve our services. We will take each feedback seriously, continuously optimize the service process, and improve the service quality to meet customers’ expectations and needs.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What safety precautions should I follow when operating a servo press machine?

When operating a servo press machine, it is important to follow all safety protocols, including wearing appropriate personal protective equipment, using safety guards and devices, and obtaining proper training on the machine’s operation. Additionally, only trained and authorized personnel should operate the machine.

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.

- Which shipping way can you provide?

We can provide shipping by sea, by air, by express and etc according to customer requirements.

- What are the advantages of servo presses in forging?

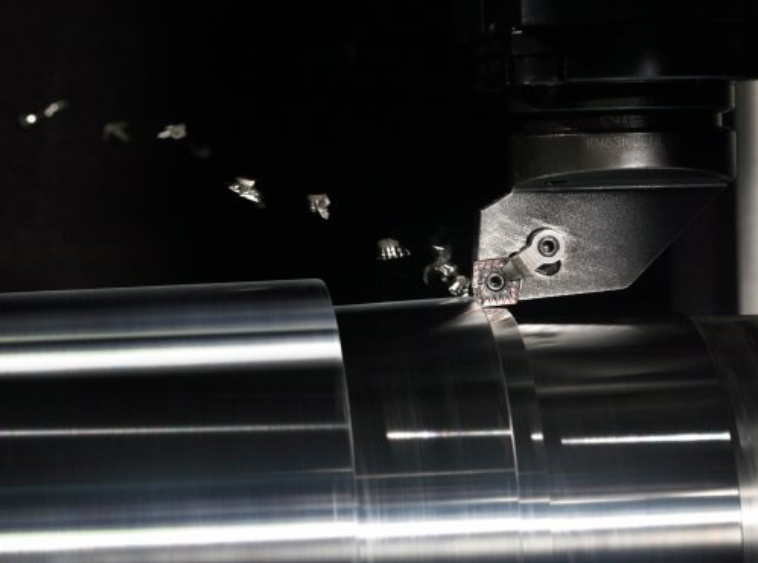

In addition to making it possible to form materials traditionally considered difficult to machine, our servo presses offer a number of other benefits, including higher forming accuracy, increased productivity, reduced noise, and improved energy savings.

- Which payment terms you can accept?

We can accept flexible payment methods including Bank Transfer, LC, DP, Western Union, Paypal or combined terms as negotiated.

- What is Double Station Turntable Servo Riveting Machine?

The Double Station Rotary Table Servo Riveting Machine consists of a cast body, a double station rotary table, a servo riveting system, a human computer interaction system, and a safety protection system.

- What is the maintenance required for a servo press machine?

A servo press machine requires regular maintenance, including lubrication, checking for wear of components, and calibration of the servo motor. Regular maintenance ensures optimal performance and longevity of the machine.

- What is a servo linear actuator mechanism?

The servo motor is directly connected with the transmission screw of the electric cylinder, so that the encoder of the servo motor directly feeds back the displacement of the moving piston of the electric cylinder, which reduces the inertia and clearance of the intermediate link, and improves the control and control accuracy.

- What are the advantages of using a servo press machine?

The advantages of using a servo press machine include reduced production costs, increased productivity, improved product quality, and better energy efficiency.

- How many types of riveting machines do we have in our factory?

Our factory has S / C type precision intelligent servo press equipment, high precision diameter riveting, pendulum riveting, servo rotary riveting machine.