선형 서보 프레스

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Which shipping way can you provide?

We can provide shipping by sea, by air, by express and etc according to customer requirements.

- How is a servo press machine different from a mechanical press machine?

A servo press machine differs from a mechanical press machine in that it employs a servo motor that provides precise control over the ram’s position and speed, while a mechanical press machine uses a flywheel and clutch to control the ram.

- Do you have an inspection procedure for the product?

Yes, We have a strict inspection of product quality and packing.

- Which payment terms you can accept?

We can accept flexible payment methods including Bank Transfer, LC, DP, Western Union, Paypal or combined terms as negotiated.

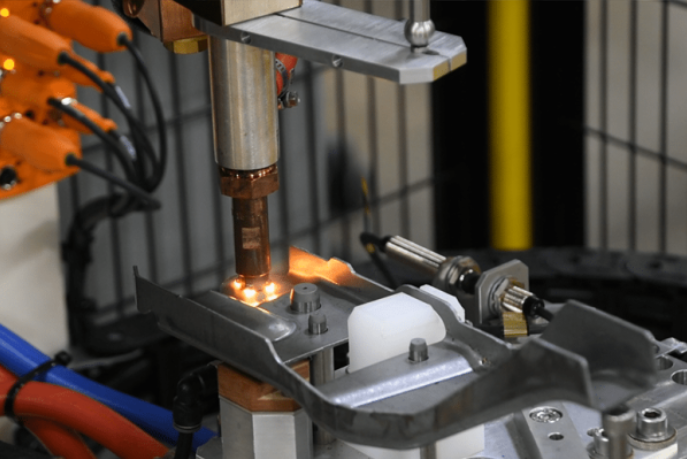

- How many types of riveting machines do we have in our factory?

Our factory has S / C type precision intelligent servo press equipment, high precision diameter riveting, pendulum riveting, servo rotary riveting machine.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.

- What is a servo linear actuator mechanism?

The servo motor is directly connected with the transmission screw of the electric cylinder, so that the encoder of the servo motor directly feeds back the displacement of the moving piston of the electric cylinder, which reduces the inertia and clearance of the intermediate link, and improves the control and control accuracy.

- What is a servo press machine?

Guangdong pinjialing Intelligent Technology Co. , Ltd is a professional to servo pressing, Precision coating and Related Equipment R & D and manufacturing as one of the modern technology-based companies. Servo press machines consist of many components, including a servo motor, servo driver, lead screw, PLC, touch screen, timing pulley, timing belt, guide rod, bearings, power switch, and thermal protection.

- What is a servo press machine?

A servo press machine is a type of press machine that uses a servo motor to drive the ram. It provides precise control over the stroke and speed of the ram, allowing for accurate and repeatable forming processes.

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.