Precisie kwantitatieve klep KST-550 product

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- How does an electric churn work?

The Electric Butter Machine has a motorized churn that rotates and agitates the cream, causing the fat globules to coalesce and separate from the buttermilk, resulting in fresh butter.

- Is it safe to use?

Yes, the Electric Butter Machine is safe when used according to the manufacturer’s instructions. Always follow the safety guidelines and precautions outlined in the instruction manual.

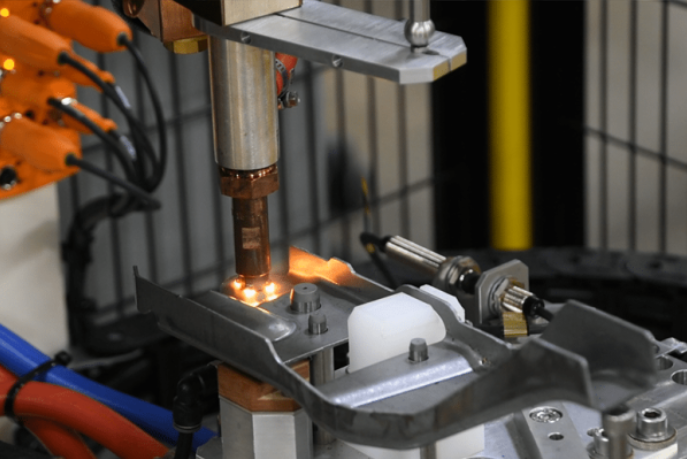

- What types of materials can be formed using a servo press machine?

A servo press machine can be used to form a variety of materials, including steel, aluminium, copper, and other alloys.

- What are the advantages of servo presses in forging?

In addition to making it possible to form materials traditionally considered difficult to machine, our servo presses offer a number of other benefits, including higher forming accuracy, increased productivity, reduced noise, and improved energy savings.

- What are the advantages of using a servo press machine?

The advantages of using a servo press machine include reduced production costs, increased productivity, improved product quality, and better energy efficiency.

- How to place order?

When you are ready to order, please contact us for confirm the suitable solution & plan & model. What cannot be ignored is you should provide a copy purchase order to ensure that your order is processed properly.

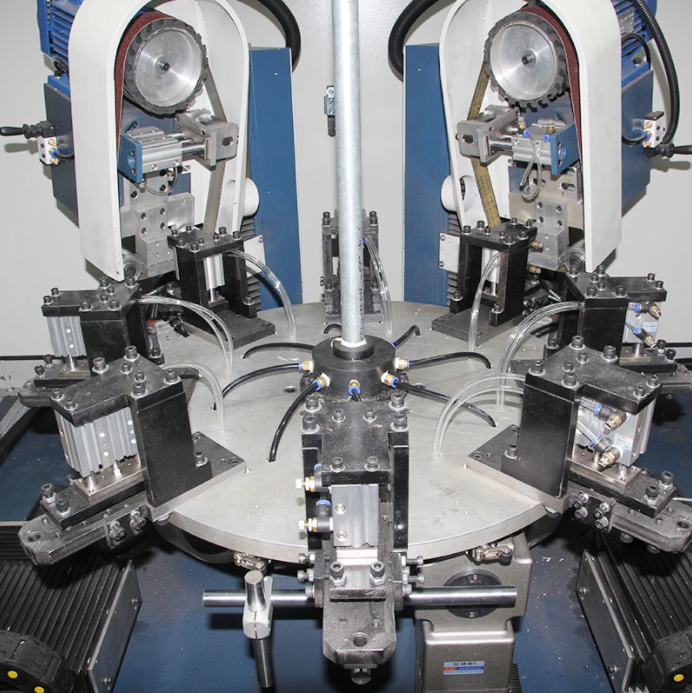

- What is a servo press machine?

A servo press machine is a type of press machine that uses a servo motor to drive the ram. It provides precise control over the stroke and speed of the ram, allowing for accurate and repeatable forming processes.

- Which payment terms you can accept?

We can accept flexible payment methods including Bank Transfer, LC, DP, Western Union, Paypal or combined terms as negotiated.

- Is there any warranty after purchasing the servo press?

We have more than 13 years of professional manufacturing experience. We provide 2 years warranty for our servo presses. Technical support is provided free of charge forever.

- What is a Nano silver sintering machine?

Our nanosilver sintering machine is an efficient and environment-friendly nanomaterial preparation equipment product, which focuses on the sintering preparation of high quality nanosilver powder. The product adopts advanced microwave heating technology to effectively control the temperature field distribution and ensure uniform and stable sintering process. Equipped with a sophisticated vacuum system and exhaust gas treatment device to ensure that the sintering process is carried out in a dust-free, low-oxygen environment, thereby improving the purity and dispersion of nanosilver powder.