Sproeiventiel KST-810P product

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is a servo linear actuator mechanism?

The servo motor is directly connected with the transmission screw of the electric cylinder, so that the encoder of the servo motor directly feeds back the displacement of the moving piston of the electric cylinder, which reduces the inertia and clearance of the intermediate link, and improves the control and control accuracy.

- How do I select the right servo press machine for my application?

When selecting a servo press machine, it is important to consider factors such as the required forming force and stroke, the material to be formed, and the required production volume. Consult with a reputable supplier to ensure that the machine meets your needs and requirements.

- How to place order?

When you are ready to order, please contact us for confirm the suitable solution & plan & model. What cannot be ignored is you should provide a copy purchase order to ensure that your order is processed properly.

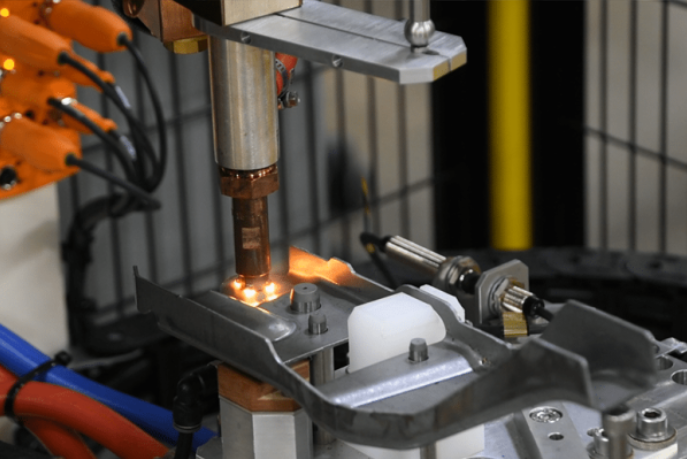

- What is a Desktop Servo Riveting Machine?

Desktop Servo Riveting Machine are high-torque machines. They are able to produce the output pressing force with full energy at any point of an operation.

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.

- What is a servo press machine?

Guangdong pinjialing Intelligent Technology Co. , Ltd is a professional to servo pressing, Precision coating and Related Equipment R & D and manufacturing as one of the modern technology-based companies. Servo press machines consist of many components, including a servo motor, servo driver, lead screw, PLC, touch screen, timing pulley, timing belt, guide rod, bearings, power switch, and thermal protection.

- What is a servo press machine?

A servo press machine is a type of press machine that uses a servo motor to drive the ram. It provides precise control over the stroke and speed of the ram, allowing for accurate and repeatable forming processes.

- Is it safe to use?

Yes, the Electric Butter Machine is safe when used according to the manufacturer’s instructions. Always follow the safety guidelines and precautions outlined in the instruction manual.

- What is a Nano silver sintering machine?

Our nanosilver sintering machine is an efficient and environment-friendly nanomaterial preparation equipment product, which focuses on the sintering preparation of high quality nanosilver powder. The product adopts advanced microwave heating technology to effectively control the temperature field distribution and ensure uniform and stable sintering process. Equipped with a sophisticated vacuum system and exhaust gas treatment device to ensure that the sintering process is carried out in a dust-free, low-oxygen environment, thereby improving the purity and dispersion of nanosilver powder.