Multifunctional servo riveting machine

Main technical parameters

| technical indicators | PJL-BM0.5T | PJL-BM1T | PJL-BM2T | PJL-JM2T | PJL-BM3T | PJL-BM5T | PJL-BM10T |

| Riveting capacity (mm) | Ø2- Ø6 | Ø2- Ø9 | Ø2- Ø12 | Ø2- Ø6 | Ø2- Ø16 | Ø2- Ø20 | Ø2- Ø30 |

| Maximum spin riveting pressure (N) | 5000 | 10000 | 20000 | 20000 | 30000 | 50000 | 100000 |

| Maximum working stroke(mm) | 100 | 100 | 150 | 100 | 100 | 100 | 100 |

| Closed height(mm) | 250 | 250 | 220 | 220 | 250 | 250 | 250 |

| Keeldiepte (mm) | 110 | 110 | 150 | 150 | 150 | 150 | 150 |

| Protrusion length of rivet head(mm) | 50 | 50 | 50 | 45 | 50 | 50 | 50 |

| Table size(mm) | 300X200 | 300X200 | 500X300 | 500X300 | 500X300 | 500X300 | 500X300 |

| using electric | AC220 | AC220 | AC380 | AC380 | AC380 | AC380 | AC380 |

| Power Consumption (W) | 1500 | 2000 | 3200 | 3200 | 7300 | 9900 | 11900 |

| motor steering | clockwise | clockwise | clockwise | clockwise | clockwise | clockwise | clockwise |

| Note: The riveting capacity is based on solid Q235 (A3) steel. If the rivet material is non-ferrous metal, hollow nail, the riveting capacity can be enlarged as appropriate | |||||||

|

A multifunctional servo riveting machine is a versatile industrial tool designed to perform riveting operations with the assistance of a servo motor. Riveting is a process used to join or fasten materials together by deforming and compressing a metal pin or rivet. These machines are commonly used in manufacturing, automotive, aerospace, and other industries where strong and reliable fastening is required.

Applications

Auto-industrie

Aerospace Industry

Electronics and Electrical

Metal Fabrication

Construction Industry

Renewable Energy

Medical Devices

Furniture Manufacturing

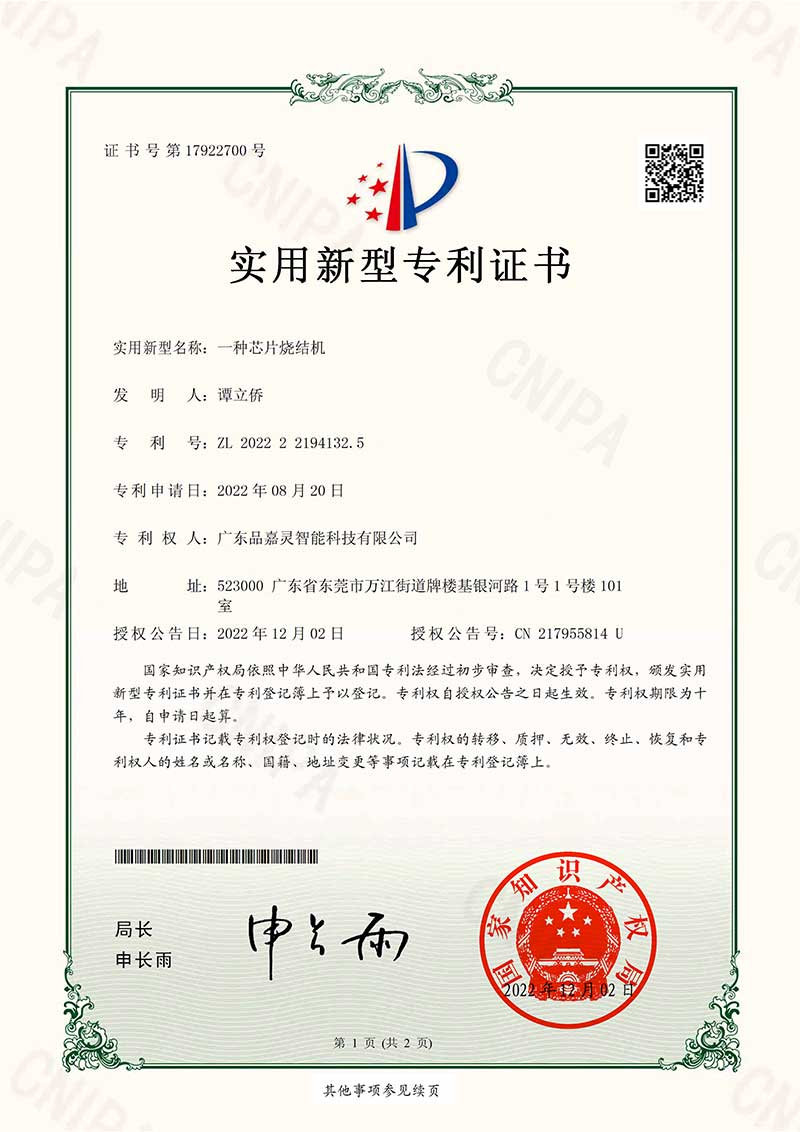

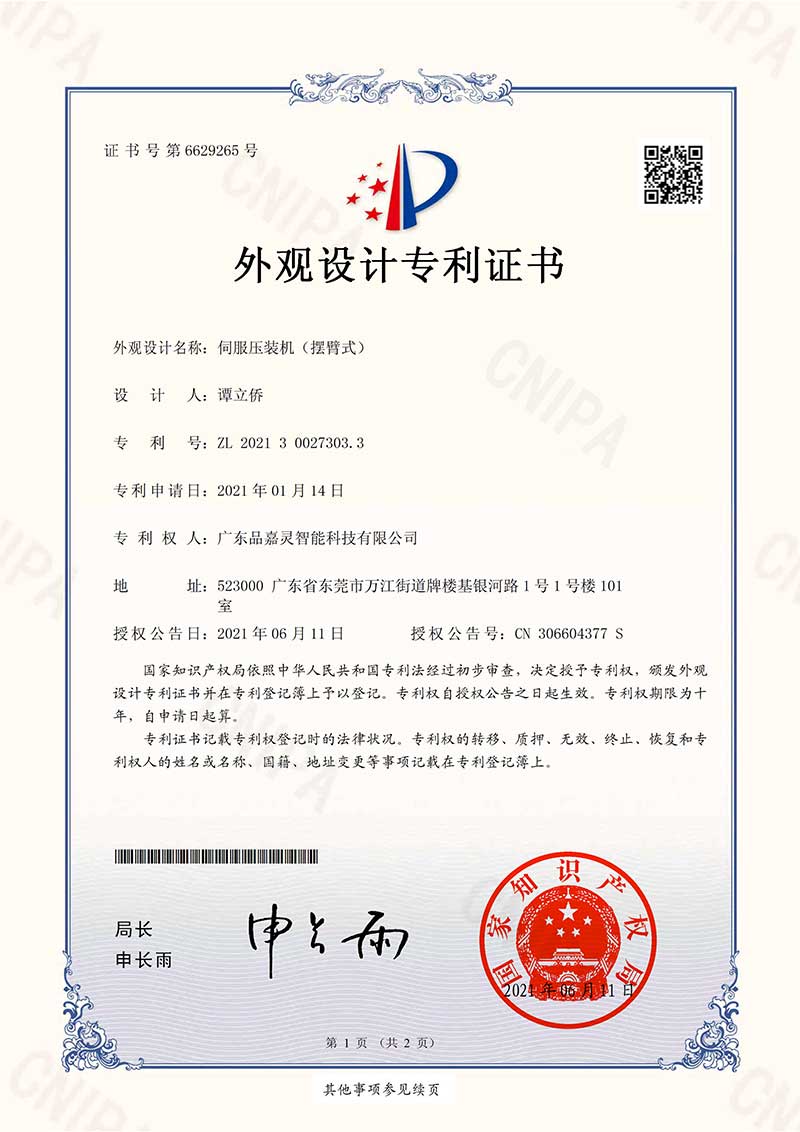

We have obtained various international management system certifications and comply with production standards in different regions.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!