Настольный клепальный станок с сервоприводом

Wide variety of precision press control methods

Equipped with an AC servomotor and internal load cell for position-based and load-based control with modifiable press-fit speed control, servo presses offer work-oriented operational flexibility.

Saves energy and improves the work environment

Not only do servo presses run quieter and cleaner for both the operator and the workpiece, but servo presses also consume only about 10~20% of the electricity used by conventional air and oil presses.

Comprehensive traceability data

With a servo press, the built-in AC servomotor and internal load cell not only provide pressing result data, but can also display and store position and load value data as a waveform graph.

|

|

MACHINE FEATURES:

Extremely fast and quiet servo motor. Speed of 30 punches per minute.

Automatic safety mechanism. The machine will not punch until the dies are closed, protecting the operator from injury.

Automatic adjustment technology. Adjusts to different fabric thicknesses, making it easy for anyone to use.

Energy Efficient. Significant energy savings (less than 0.2 kilowatts per hour for 12 hours of use compared to 3 kilowatts for non-servo electric presses).

LED Position Indicator. A bright red laser guides the user and ensures accurate grommet placement.

Stand includes storage holders, drawer and measurement guides.

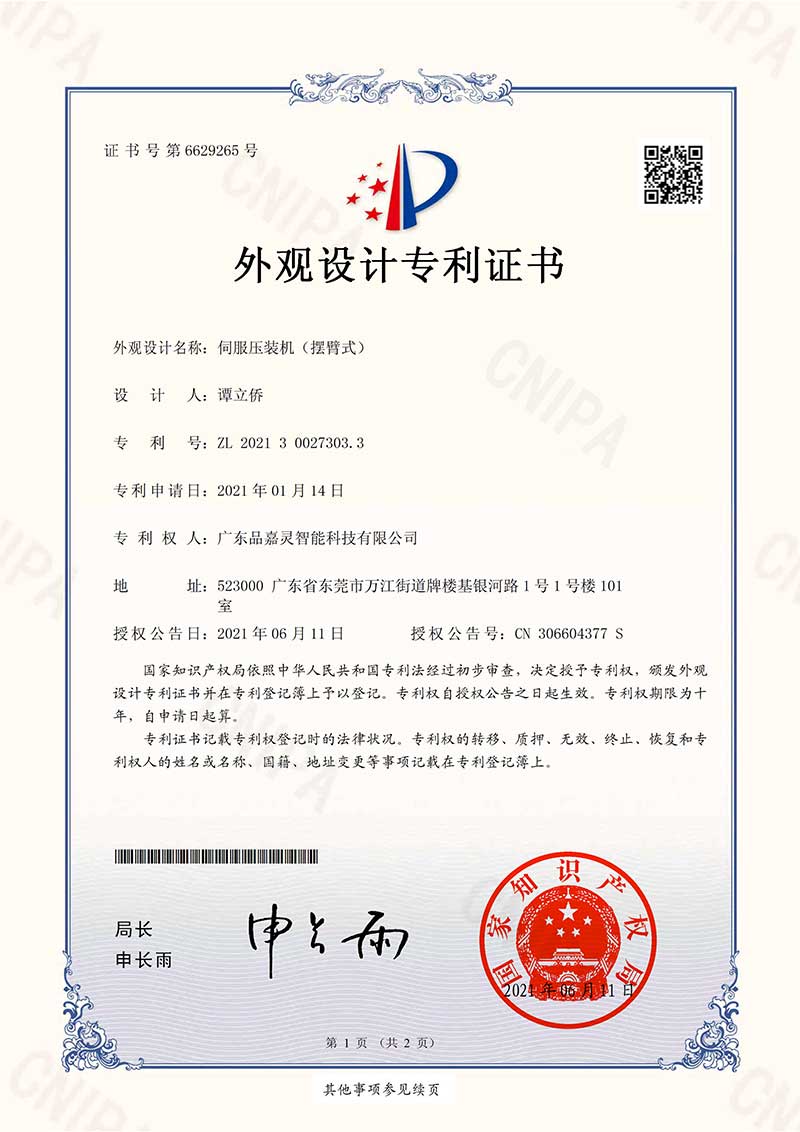

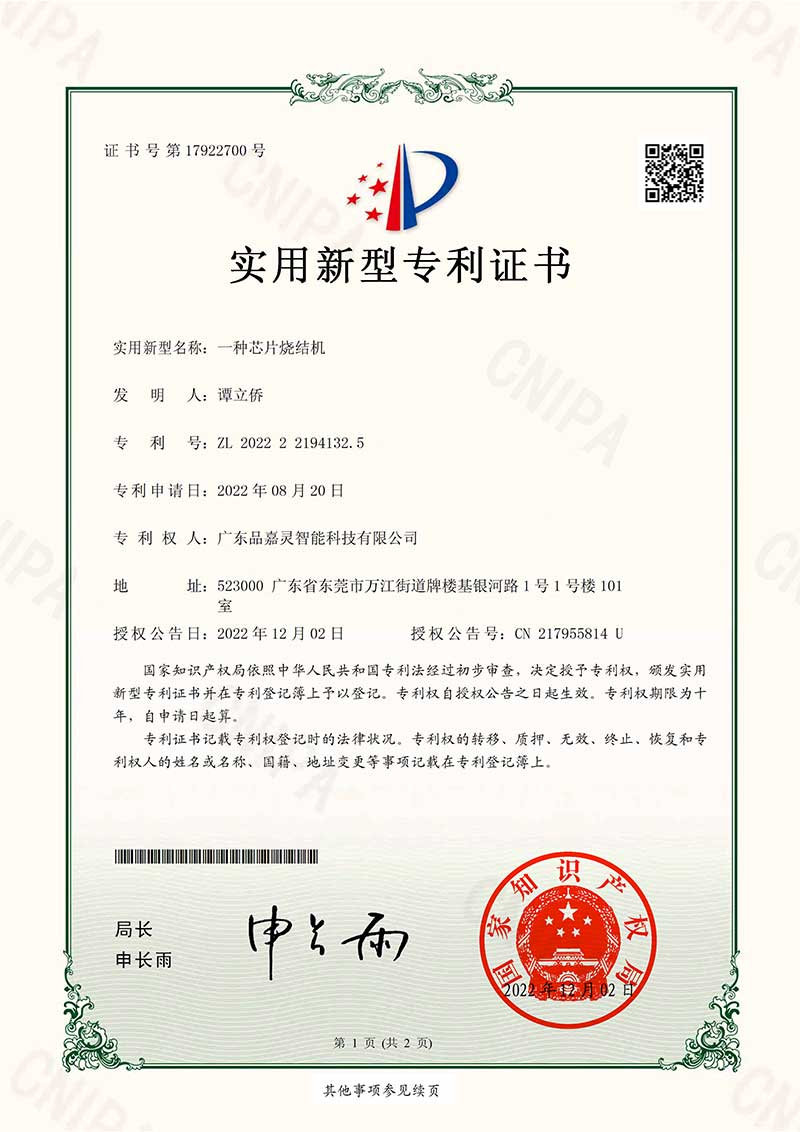

We have obtained various international management system certifications and comply with production standards in different regions.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What types of materials can be formed using a servo press machine?

- How is a servo press machine different from a mechanical press machine?

- What is the maintenance required for a servo press machine?

- What safety precautions should I follow when operating a servo press machine?