China Desktop Four-Post Press Machine

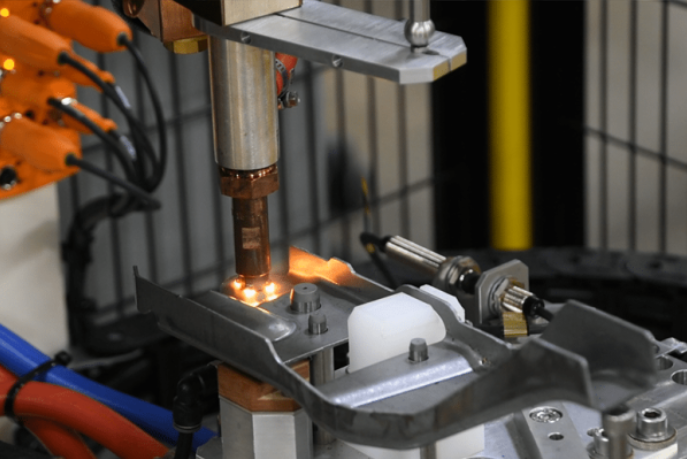

The servo press is an efficient and precise device whose core power comes from an AC servo motor. This motor not only provides excellent stability and reliability, but also ensures constant performance over long periods of operation. The servo press skillfully uses high-precision ball screws to convert the rotational force of the motor into vertical force, providing a powerful driving force for various processing tasks.

Servo presses are also equipped with encoders for precise control of speed and position. By monitoring and adjusting the encoder in real time, the machine can achieve a high degree of accuracy and reliability during processing. The servo press can apply appropriate pressure to the workpiece according to the specific processing requirements, thus achieving the ideal processing effect.

Pressure/stop position/drive speed/stop time can be controlled at any time. It can realize closed-loop control of the entire process of pressing force and pressing depth during press-fitting operations; the touch screen human-machine interface is friendly, intuitive and easy to operate. It is equipped with safety light curtains. During the installation process, if someone reaches into the installation area, the press head will stop in place to ensure safe operation.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What types of materials can be formed using a servo press machine?

A servo press machine can be used to form a variety of materials, including steel, aluminium, copper, and other alloys.

- How to place order?

When you are ready to order, please contact us for confirm the suitable solution & plan & model. What cannot be ignored is you should provide a copy purchase order to ensure that your order is processed properly.

- What are the advantages of using a servo press machine?

The advantages of using a servo press machine include reduced production costs, increased productivity, improved product quality, and better energy efficiency.

- Is there any warranty after purchasing the servo press?

We have more than 13 years of professional manufacturing experience. We provide 2 years warranty for our servo presses. Technical support is provided free of charge forever.

- Do you have an inspection procedure for the product?

Yes, We have a strict inspection of product quality and packing.

- Is it easy to use?

Yes, it’s easy to use. Just pour cream into the machine, turn it on and let it do the churning for you.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.

- How do I select the right servo press machine for my application?

When selecting a servo press machine, it is important to consider factors such as the required forming force and stroke, the material to be formed, and the required production volume. Consult with a reputable supplier to ensure that the machine meets your needs and requirements.

- Which payment terms you can accept?

We can accept flexible payment methods including Bank Transfer, LC, DP, Western Union, Paypal or combined terms as negotiated.

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.