China Desktop press machine Manufacturer

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is the maintenance required for a servo press machine?

A servo press machine requires regular maintenance, including lubrication, checking for wear of components, and calibration of the servo motor. Regular maintenance ensures optimal performance and longevity of the machine.

- Which shipping way can you provide?

We can provide shipping by sea, by air, by express and etc according to customer requirements.

- Is it easy to use?

Yes, it’s easy to use. Just pour cream into the machine, turn it on and let it do the churning for you.

- What are the advantages of using a servo press machine?

The advantages of using a servo press machine include reduced production costs, increased productivity, improved product quality, and better energy efficiency.

- How to place order?

When you are ready to order, please contact us for confirm the suitable solution & plan & model. What cannot be ignored is you should provide a copy purchase order to ensure that your order is processed properly.

- How is a servo press machine different from a mechanical press machine?

A servo press machine differs from a mechanical press machine in that it employs a servo motor that provides precise control over the ram’s position and speed, while a mechanical press machine uses a flywheel and clutch to control the ram.

- What is the use of Servo Riveting Machine?

Guangdong Pinjialing Intelligent Technology Co. Ltd. is a professional servo press, precision coating and related equipment R & D and manufacturing as one of the modern technology-based enterprises. Our servo riveting machine is used to automatically set (press) rivets to join materials together. The riveting machine offers greater consistency, productivity and lower cost compared to manual riveting.

- What safety precautions should I follow when operating a servo press machine?

When operating a servo press machine, it is important to follow all safety protocols, including wearing appropriate personal protective equipment, using safety guards and devices, and obtaining proper training on the machine’s operation. Additionally, only trained and authorized personnel should operate the machine.

- What types of materials can be formed using a servo press machine?

A servo press machine can be used to form a variety of materials, including steel, aluminium, copper, and other alloys.

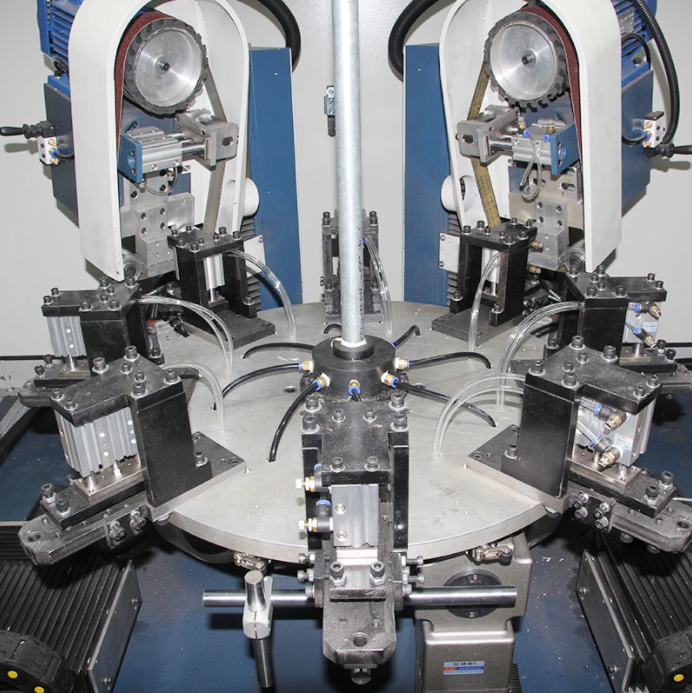

- What is a servo press machine?

Guangdong pinjialing Intelligent Technology Co. , Ltd is a professional to servo pressing, Precision coating and Related Equipment R & D and manufacturing as one of the modern technology-based companies. Servo press machines consist of many components, including a servo motor, servo driver, lead screw, PLC, touch screen, timing pulley, timing belt, guide rod, bearings, power switch, and thermal protection.