Spray valve KST-810P product

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is the maintenance required for a servo press machine?

A servo press machine requires regular maintenance, including lubrication, checking for wear of components, and calibration of the servo motor. Regular maintenance ensures optimal performance and longevity of the machine.

- What is the accuracy of the servo press?

Positioning accuracy: (mm) : ±0.01

Pressure Accuracy (%F.S): 0.5

Displacement resolution (mm) : 0.001

- What is Double Station Turntable Servo Riveting Machine?

The Double Station Rotary Table Servo Riveting Machine consists of a cast body, a double station rotary table, a servo riveting system, a human computer interaction system, and a safety protection system.

- How is a servo press machine different from a mechanical press machine?

A servo press machine differs from a mechanical press machine in that it employs a servo motor that provides precise control over the ram’s position and speed, while a mechanical press machine uses a flywheel and clutch to control the ram.

- What types of materials can be formed using a servo press machine?

A servo press machine can be used to form a variety of materials, including steel, aluminium, copper, and other alloys.

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.

- Is it safe to use?

Yes, the Electric Butter Machine is safe when used according to the manufacturer’s instructions. Always follow the safety guidelines and precautions outlined in the instruction manual.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.

- What are the advantages of using a servo press machine?

The advantages of using a servo press machine include reduced production costs, increased productivity, improved product quality, and better energy efficiency.

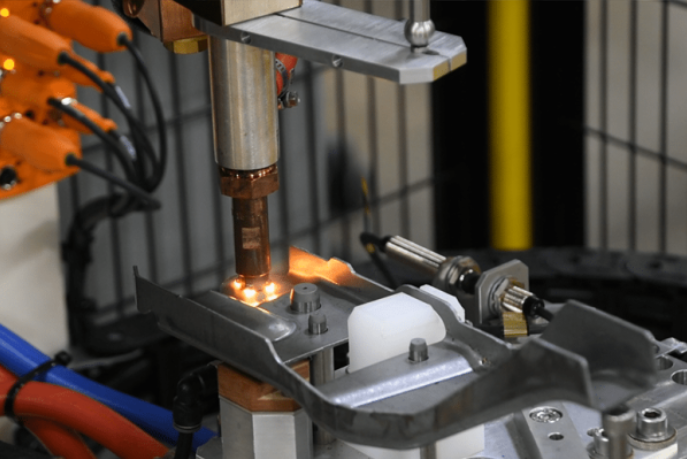

- What is Motorcycle engine cradle servo press?

Manual auxiliary loading and unloading of the cradle, automatic loading of the bushing, automatic installation of the pivot tube rubber sleeve, and automatic pressure installation of the bushing.

The equipment mainly consists of: casting frame, automatic loading and unloading system, multi-station turntable, servo pressing system, human-computer interaction system, safety protection system and other parts.